Types and Characteristics of Mainstream Lasers for 3D Printing

3D printer is a highly integrated modern device. From laser, galvanometer to control, the printer seems to be shrouded in a veil of mystery and the laser among them is even more wonderful. Laser is like a torch and is the source of energy to realize layer-by-layer manufacturing and it is also the most precise core device in a 3D printer.

The types of mainstream lasers used in 3D printing include ultraviolet lasers, fiber lasers and CO2 lasers. YAG lasers have also been used previously. 3D printers will match different lasers according to different printing materials. However, laser manufacturing as an independent industry with continuous development has undergone great changes in its matching with 3D printing processes.

There are many types of UV lasers for photo-curing such as early helium-cadmium lasers (wavelength 325nm, power 15-50mw) or argon ion lasers (wavelength 351-365nm, power 100-500mw), all of which were used in early SLA equipment and their laser beam spot size was 0.05-3mm. At present, solid-state ultraviolet lasers are commonly used in photo-curing. The output wavelength can be stabilized at 355nm, the output power is close to 800mw and adjustable while the service life is significantly increased. It can continue to be used only by replacing the laser diode.

Laser sintering technology adopts carbon dioxide laser with an output wavelength of 10.6μm, the power can range from several watts to tens of thousands of watts, the beam quality is extremely high and it is often used to process non-metallic materials (this specific wavelength has a high absorption rate) . In the laser sintering technology, the power of the CO2 laser can be selected around tens of watts and the spot diameter would be about 0.4-0.5mm which can be used to sinter non-metallic materials such as nylon, coated sand, ceramics and PS powder. In addition, early LOMs also used CO2 lasers for contour cutting.

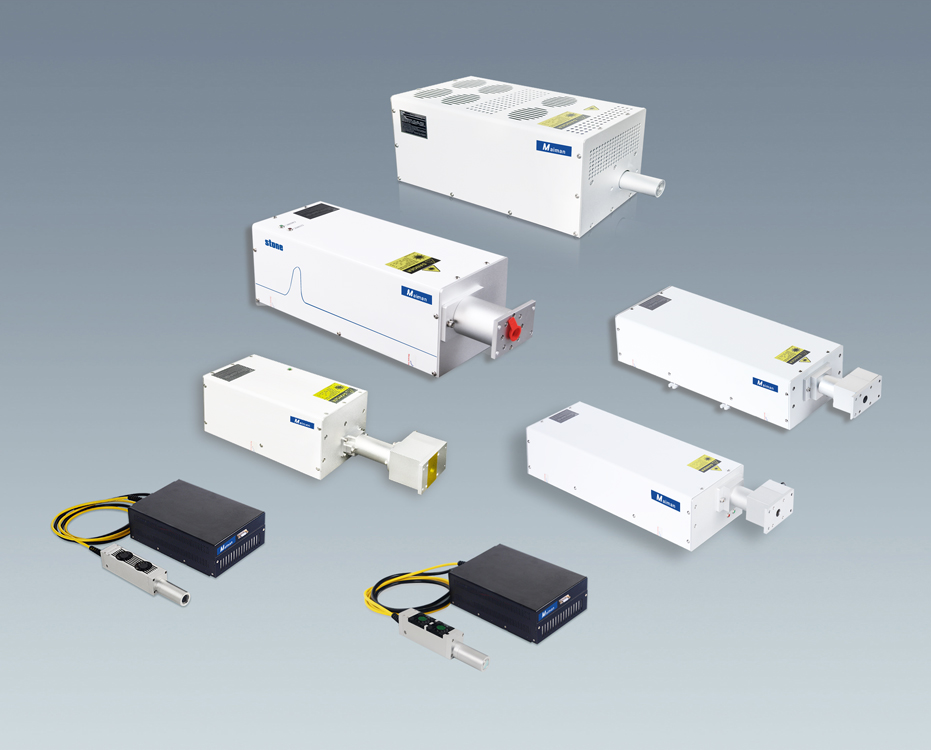

Lasers for metal printing have gone through several stages of development which consisted mainly CO2 lasers, YAG lasers and fiber lasers. The output wavelength of the CO2 laser itself is very long and the absorption rate of the metal material is low so the power of the CO2 laser used for early metal printing was often several kilowatts. The YAG laser can output a wavelength of 1.06 μm, has high coupling efficiency with metals and has good processing performance. The effective power of an 800W YAG laser is equivalent to the power of a 3KW CO2 laser. Later, as fiber lasers were gradually introduced to the commercial market, the disadvantages of YAG lasers continued to emerge. The use of fiber lasers that are more integrated, have higher electro-optical conversion rates and more stable performance has become a major trend in the development of metal printing.

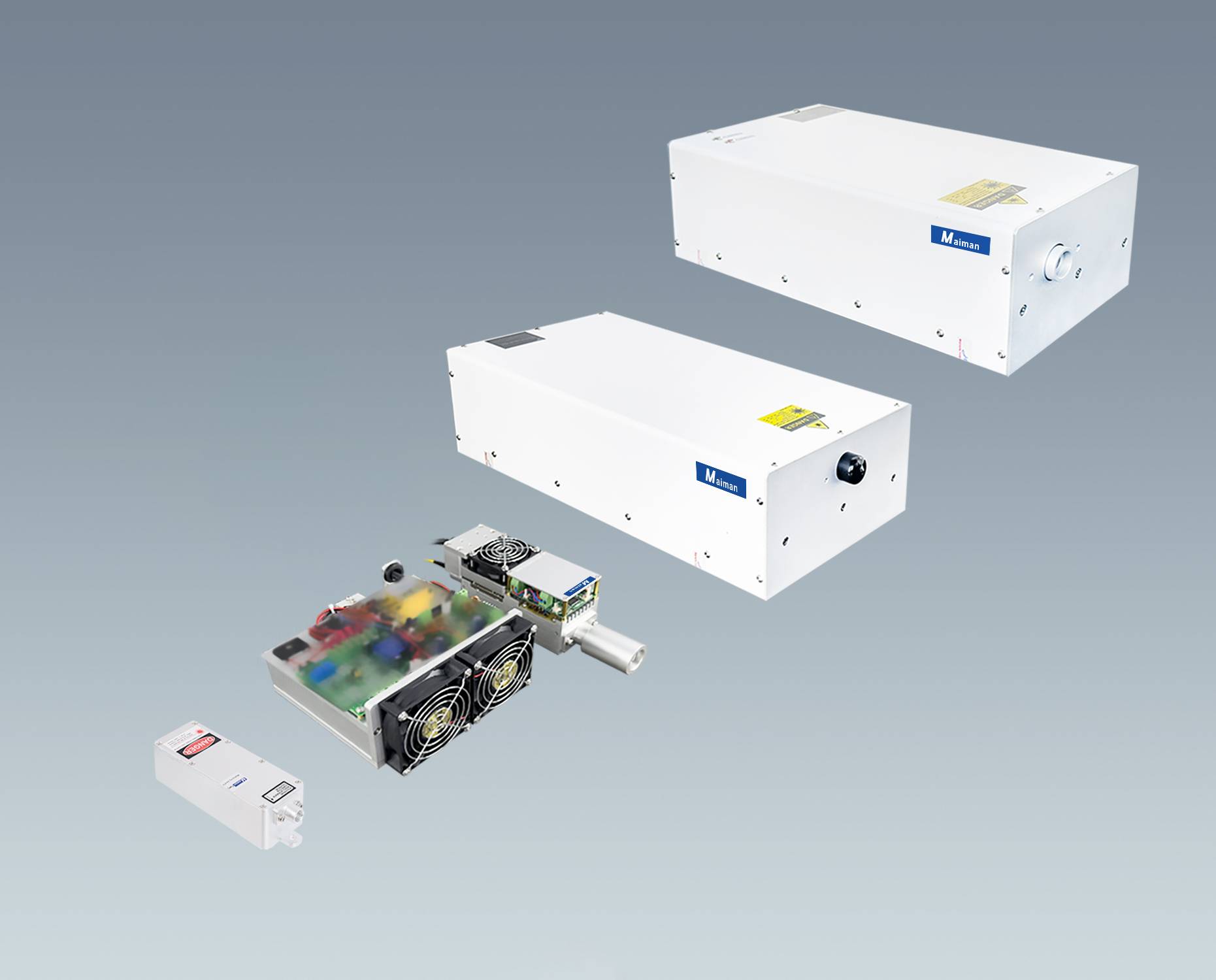

At present, although there are still few YAG lasers used for metal printing, the absolute majority has been occupied by fiber lasers. The output wavelength of fiber laser for SLM is usually 1.07μm, the peak power has several levels such as 200w, 400w, 500w, 1000w, etc., and the scanning spot is generally within 80-150μm.