Application of transparent product marking

Marking transparent products with active Q-switched lasers is becoming more and more common, with the technology being applied from the automotive industry to the 3C (computer, communications, and consumer electronics) industry and incorporated into a variety of electronic products, including transparent keyboards, electric toothbrushes, and routers. In addition, its utilization is expected to expand significantly in the future.

The complexity of marking transparent products is illustrated in the accompanying image, showcasing products with at least two layers of paint, each measuring only a few microns in thickness. Precise laser marking requires careful control to selectively remove the black paint from the surface, revealing the underlying red and blue colours. It is imperative to ensure that the paint layer beneath remains is undamaged, with edges appearing neat and colours vibrant. This demands high precision from the active Q-switched laser system, requiring the ability to adjust parameters such as power, frequency, and pulse width. Notably, the laser must exhibit exceptional power stability, pulse stability (both less than 3%), and superior beam quality (<1.3).

Choosing the Right Laser for Transparent Products

In addressing the unique challenges of marking transparent products, The active Q-switched laser emerges as the most suitable option due to its broad processing range, enabling it to handle different colours of paint layers and varying thicknesses. In contrast, while effective, the MOPA fibre laser has a more limited processing range and is primarily suited for black paint layers.

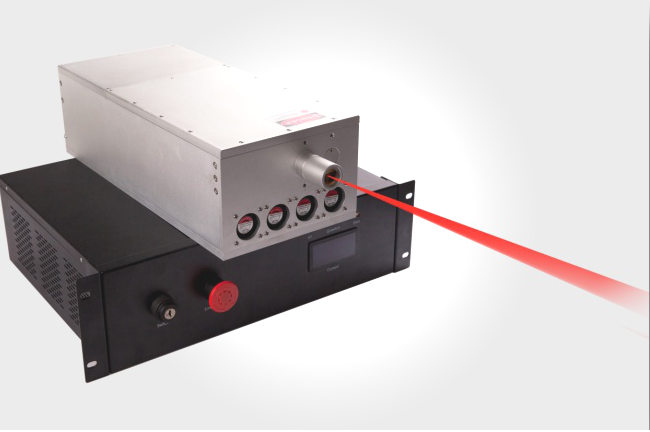

Practical Application: Maiman A Series 1064nm Q-switched Lasers

The application cases of the Maiman A Series 1064nm Q-switched lasers in transparent products exemplify the successful integration of advanced laser technology into practical industrial settings. These lasers offer several advantages, including ultra-high pulse and power stability, superior beam quality, and switching between vibration and continuous working modes. Furthermore, they demonstrate compatibility with a diverse range of materials, allowing for the marking of various colours.

In conclusion, As active Q-switched laser technology continues to evolve, it is poised to become an integral component in the manufacturing processes of a wide array of electronic products, paving the way for new possibilities and applications in the ever-expanding 3C sector.