Laser processing for PCB industry

PCB applications are experiencing a surge in popularity, with an increasing demand for high-power UV lasers in PCB processing. The integration of these lasers into the PCB industry is gaining traction due to their effectiveness and precision. As the demand for such technology rises, exploring low-cost integration routes becomes essential for manufacturers and businesses.

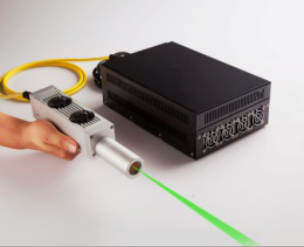

In PCB marking, high-power UV lasers are an excellent light source. Notably, the fibre-type green laser, such as the one produced by Maiman, offers a compelling alternative. This green laser option is cost-effective and delivers impressive marking results. Its application extends to insulation film marking, boasting low failure rates, a long lifespan, and easy integration into existing systems.

The fibre-type green laser’s product features include insulation film marking, low failure rates, long life, and ease of integration. These characteristics make it a viable choice for PCB marking applications, contributing to the efficiency and cost-effectiveness of the overall process.

Fiber Type Green Laser

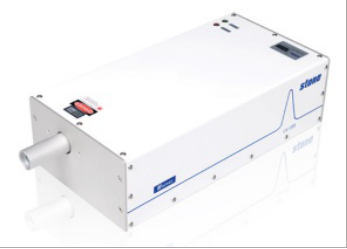

Regarding PCB cutting and drilling, UV or green lasers are commonly employed. The fibre-type green laser, however, may pose a risk of carbonization. The recommendation leans towards high-power UV lasers for applications with high cutting precision requirements. These lasers, ranging from 12W to 20W, exhibit features such as long life, maintenance-free operation, and eliminating the need for regular calibration of the light path.

The 12W-20W high-power UV lasers offer an easy-to-install, all-in-one machine solution with no additional power supply required. The galvanometer can be directly installed, further streamlining the integration process and reducing overall costs. Additionally, these lasers boast stable performance, low power consumption, minimal thermal impact, a wide application range, fast marking speed, high efficiency, small spots, and high beam quality.

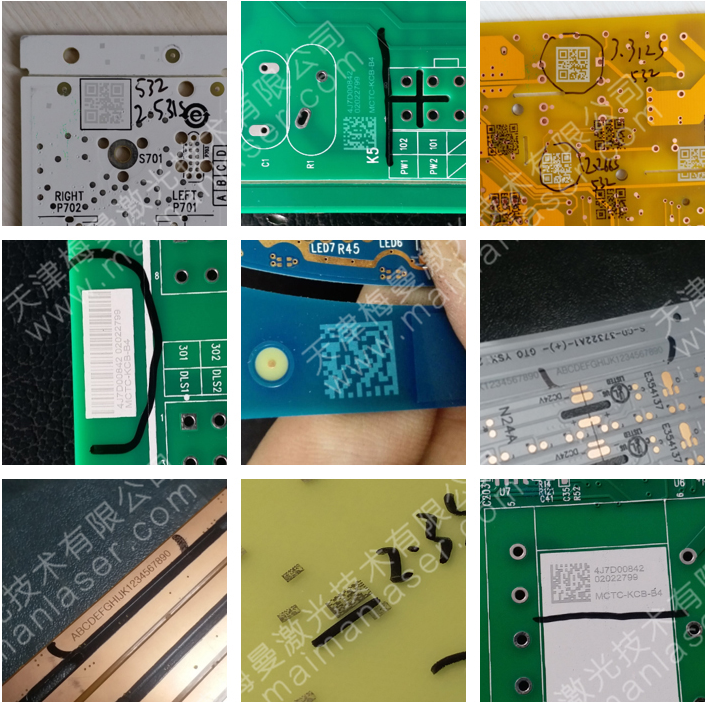

PCB Marking Cases

12W-20W High-power UV lasers

High-power UV lasers Cutting and Drilling PCB cases

Applying high-power UV lasers proves advantageous for PCB cutting and drilling cases due to their stable performance, low power consumption, minimal thermal impact, and compatibility with visual fibre racks. These lasers align well with production lines, offering fast marking speeds, high efficiency, small spots, and high beam quality, contributing to enhanced productivity in PCB manufacturing processes. Integrating such advanced laser technologies reflects the industry’s commitment to innovation and efficiency, focusing on meeting the evolving demands of PCB applications.