Black Marking On Aluminum ,Choose Maiman End Pump Laser, Low Cost and Stable

Application of Black Marking On Aluminum

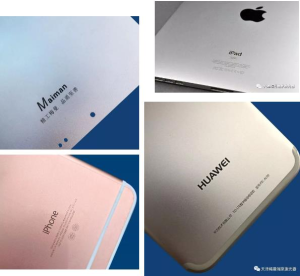

Black Marking On Aluminum is suitable for various materials such as alumina, anodized aluminium, coloured aluminium, magnesium aluminium, etc., and its application is extensive. It is mainly used in fields requiring high depth, smoothness and fineness, such as stainless steel decorations, clocks, moulds, IC, mobile phone buttons and other industries. Our most common Apple iPhone, iPad tablet and other brands of mobile phones’ aluminium back cover can be blackened with logo, text, etc. Bitmap marking can mark exquisite patterns on metal, plastic and other surfaces.

▲Principle of Black Marking On Aluminum

Laser marking is a processing method that uses a high-energy-density laser to irradiate the workpiece to vaporize the surface material or undergo a chemical reaction of colour change, leaving a permanent mark. The blackening technology of the laser marking machine is related to anodized aluminium.Due to the nano effect after laser treatment, the size of oxide particles becomes nanometre level, which causes the light absorption performance of the material to be increased so that visible light is absorbed on the material and reflected. Since very little visible light is coming out, it seems black to the naked eye.

The Choice of Laser

The blackening of metal materials such as stainless steel can be easily achieved by fibre laser marking. Still, high-reflection materials such as copper and aluminium can only be grey-black, and it isn’t easy to attain transparent black. Therefore, the Maiman Laser provides you with unique options for blackening. F series 1064nm cold light laser has a narrow pulse width and high peak power, while fibre laser has too wide and low peak value. Compared with fibre laser, end-pumping has apparent advantages. It can achieve better blackening effect.

F series 1064nm cold light laser.

Application advantages:

- Ultra-high peak power, 8W cold light laser is six times the peak power of 20W fibre laser

- Narrow pulse width, high peak power, wide range of applications

- Anti-high reflection, gold/silver/copper marking does not damage the laser

- High precision, more delicate than fibre laser processing

- High performance, high reliability, ultra-low price, longer life

▲Application Cases of Black Marking On Aluminum

▲Advantages of Black Marking On Aluminum Laser Processing

Permanence: The blackening effect will not fade due to environmental relations such as touch, high and low temperature, acidity and alkalinity.

Low cost: Laser blackening is a one-time formation; no auxiliary materials or manpower are needed, and the consumption is negligible.