UV Lasers Makes Important Breakthrough in High-Power Maiman Lasers

High-power UV lasers are widely used in wafer scribing, ceramic substrate cutting, silicon-based substrate drilling, FPC cutting and many other fields. With the continuous improvement of processing fineness and production efficiency, the requirements for the beam quality, output power and stability of UV lasers are getting higher and higher. Maiman Laser has been committed to the development and innovation of laser technology for a long time, especially in high-power UV lasers; it has done a lot of innovative and pioneering work and has developed high-power, high-beam quality, and high-stability UV lasers to meet the needs of laser micromachining.

Through in-depth research on UV laser technology, Maiman Laser has summarized three significant factors that affect the power improvement and long-term stability of UV lasers: the thermal effect, the damage of the triple frequency crystal, the imbalance of the optical path and the long-term strength. Solving the technical bottlenecks in these three aspects dramatically improves the performance of the UV laser, thereby realizing the UV laser with high power, beam quality and high stability.

Regarding the thermal effect of lasers

Maiman Laser has led the way in developing wavelength-locked laser diode resonance pumping technology in China. By optimizing different crystal parameters (doping concentration, temperature, length) and pump parameters (pump power density and mode matching), the thermal effect of the laser is effectively reduced, and the mode volume of the oscillating light is increased, the light conversion efficiency and beam quality of the fundamental frequency light are improved. It provides a vital precondition for realizing high-power UV laser output.

Regarding the anti-damage of frequency triple crystals

Maiman Laser reasonably designed the laser resonator to meet the mode-matching conditions while reducing the optical power density of the end face of the triple-frequency crystal and increasing the upper limit of the output power of UV lasers. At the same time, the gas microcirculation system and the de-metallization technology in the cavity are used to control the volatiles generated in the cavity effectively and improve the service life of the triple-frequency crystal.

Regarding optical path misalignment and long-term stability

Maiman Laser adopts unique optical path compensation technology and optimization of the resonator to reduce the optical resonator’s misalignment sensitivity and improve the optical path’s strength. In terms of mechanical structure, through the automated analysis and calculation of the laser housing and optical-mechanical parts, a highly stable visual, automatic system is designed, and the deformation of the material is reduced through unique processing methods and heat treatment schemes to ensure the long-term stability of the laser.

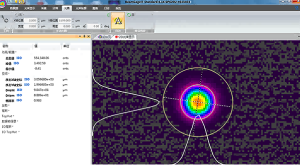

Through multi-dimensional technical research on high-power UV lasers, Maiman Laser has developed a 30W-class, long-life 355nm UV laser with high power, beam quality, and stability. The laser can meet the high-intensity use environment of 7x24h and maintain long-term stability. It can be widely used in the field of laser micromachining.

With its strong innovation ability, Maiman Laser has won a good market reputation and a broad customer base and covers a variety of laser products from infrared to ultraviolet, from continuous to pulsed. The company adheres to scientific and technological innovation, industry serving society, the craftsman spirit of perfection, down-to-earth development, making every product well and serving every customer.