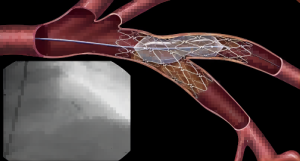

Laser Cutting Cardiovascular Stent

Enter laser-cutting machines, a technological marvel that has become a driving force in the medical device industry. The cardiovascular stent, a crucial component in treating blocked veins or arteries post-angioplasty, demands meticulous precision and a pollution-free composition. Traditional processing methods often need to improve environmental sustainability and the structural integrity required for a smooth, burr-free stent surface.

Advantages of Laser Cutting

That machine, primarily utilized for its high precision and rapid computer software-driven capabilities, has found a significant application in crafting cardiovascular stents. The advantages they bring to the table are manifold.

High Precision and Speed:

Propelled by advanced computer software, that machine ensures unparalleled precision and swift processing. The automated control software interface allows real-time feedback, enabling timely and accurate adjustments.

Non-Contact Processing:

Unlike traditional methods, laser cutting involves non-contact processing. This eliminates the risk of mechanical stress and deformation and contributes to a cleaner, pollution-free end product.

Burr-Free Cutting:

Laser-cutting machines excel in producing burr-free edges, a crucial requirement for cardiovascular stents. The intricate design patterns are executed precisely, minimizing residual thermal effects.

Application in Stent Manufacturing:

Thin-walled tubes, essential in stent fabrication, are expertly cut using laser cutting machines. The laser removes excess metal, creating a robust bracket that can withstand external forces. The laser device is the go-to technology for this intricate task, renowned for its efficiency and precision.

As laser processing continues its rapid evolution, laser welding and marking machines also significantly contribute to various industries. Initially developed for medical equipment and fabric cutting, laser cutting machines have proven their versatility and indispensability in diverse fields.

In conclusion, laser cutting technology is an unyielding force, transforming the manufacturing landscape of medical devices such as cardiovascular stents and leaving an indelible mark in the broader spectrum of industrial applications. Its precision, speed, and versatility make it a cornerstone in modern manufacturing.