Diamonds Processing by Laser : Paving the Way for Future Innovations

As science and technology progress, the cultivation of diamonds has evolved, giving rise to two main categories: CVD diamonds and HPHT diamonds. In this exploration, we focus on understanding the significance of CVD diamond processing.

The Essence of CVD Diamonds

CVD diamonds, short for “Chemical Vapor Deposition,” represent a groundbreaking method in synthetic diamonds. This technique involves the deposition of carbon atoms onto a suitable substrate, creating a diamond lattice structure through a high-temperature and high-pressure process using a chemical gas, typically carbon-containing.

CVD Diamond Processing:

Selection of Precursor Gas: Utilizing carbon-containing gases, such as methane, as precursor materials under high-temperature and high-pressure conditions.

Deposition Process: The precursor gas is introduced into the reaction chamber, where pyrolytic decomposition releases carbon atoms, depositing them onto a suitable substrate to form the diamond lattice.

Control Parameters: Precise control of temperature, gas flow, pressure, etc., to ensure the quality and properties of the resulting diamonds.

Post-Treatment and Processing: Following deposition, CVD diamonds may undergo additional processing steps tailored for specific applications, like grinding, polishing, and cutting.

CVD Diamonds in Industrial Applications and Advantages:

While historically defined as “diamonds that last forever” and prized as jewellery, CVD diamonds have transcended their decorative role. Industrial applications now harness their unique advantages:

High Thermal Conductivity: CVD diamonds dissipate heat, making them ideal heat sinks in high-power semiconductors, enhancing performance and preventing overheating.

Electrical Insulation: As an electrical insulator at room temperature, CVD diamonds insulate layers, preventing current leakage and electronic interference in semiconductor devices.

Irradiation Resistance: CVD diamonds exhibit stability in highly irradiated environments, making them suitable for nuclear, space, and other electronic devices.

Chemical Stability: Exceptional chemical stability enables using CVD diamonds in environments with corrosive chemicals, making them suitable for various industrial processes.

Biocompatibility: The biocompatibility of CVD diamonds opens avenues in biomedical fields, promising applications in biosensors and biomedical instruments.

Highest Hardness: With outstanding hardness, CVD diamonds are employed in cutting-edge micro-mechanical systems (MEMS) devices, crucial in the semiconductor industry, especially in sensors and microfluidic applications.

Maiman’s solution for diamond processing:

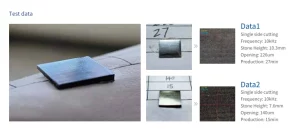

Recognizing the wide range of applications of CVD diamonds, Maiman Laser is at the forefront of research and development. DIAMOND series solid-state lasers are designed for the precision processing of carbon materials and super-hard materials. This laser provides diamond cutting, diamond drilling, diamond marking, and other solutions for diamond processing and can achieve a depth of more than 3 mm on super-hard materials.

The product’s single pulse energy is >2mj, superior beam quality (M2<1.3), long life, maintenance-free, all-in-one machine, and highly integrated. Have a competitive advantage in the international market.

In conclusion, CVD diamonds are a miracle in jewellery and the industry. They are changing the industry with their unparalleled features. Tianjin Maiman provides cutting-edge solutions for global diamond processing.